|

|||

| 8 | |||

| Corrugated / Liquid / Bag | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

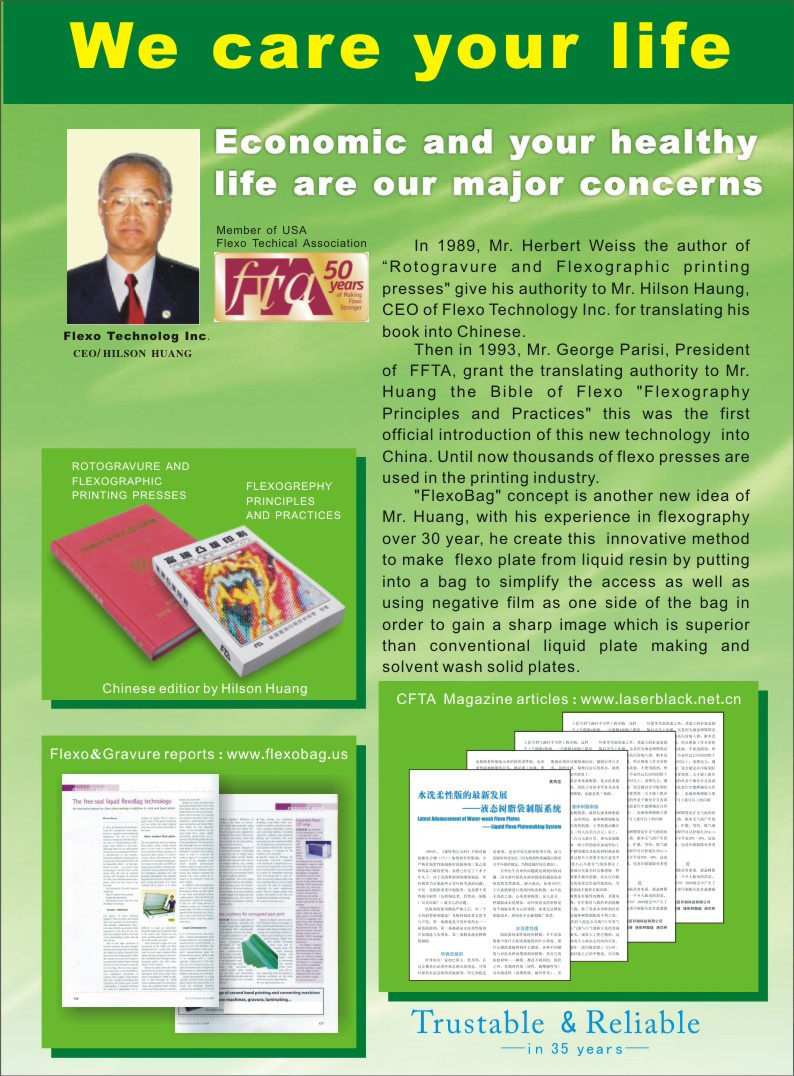

No running-in period and skilled worker required ¢w New patent @flexoBag System ¢w DJ Cartons, 35 years in package printing, located in E-Land, the eastern side of Taiwan as an isolated area before the free way was built 5 years ago due to inconvenient of transportation from city areas of Taipei which is in the western side. It had to take 4 hours to get there in the past time, nowadays only 40 minutes to go by going through a long tunnel of 13 kilometers. DJ Cartons is possessing 3 Slotting units for multiple color carton printing for the demands of packaging in eastern areas like E-Land / Hua Lien and TaiDong, now they have the ability to expend their territory to the city areas, in Taipei they have a liaison office to receive the orders now after they start their own in-plant plate making system from @flexoBag. In the past they had to rely on the trade shop in Taipei to make plates for them, it cost them NTD 150000.- (USD 5000.-) / month which is not competitive at all. The total expenses they have paid for the plate making is NTD 2,000,000 (USD 70,000) annually. The plate cost they paid for the trade shop was NTD 8.00 / per square inch, now after they have installed the @flexoBag system the total cost they are manufacturing is only 1.80 / in 2, this is also including the negative making cost from a LaserBlack Enhancer which is pretty economic and convenient way for film making, what you need with it is only a HP laser printer. The owners of two brothers are happy with this new system for it has reduced the plate cost of 75% for them, plus the time waiting for the plate delivery and the cost of transportation from west to east despite of the on-line original sending is quick now. Two ladies in the factory were assigned for training as operator of plate making for 2 days and have to join the production immediately although they have no experience about plate making before, now they feel lucky to have water wash @flexoBag system for they do not to have to stand the bad smell of washout solvent which is also toxic. Two ladies they have achieved the goal as our slogan ¡§No running-in period and skilled worker required.¡¨

Chang Yuen Paper packing Co. , Ltd. VN , Lo J1, duong NA3 ¡V DA3 KCN My Phuoc II, Huyen Ben Cat Tinh Binh Duong , Vietnam Experiencing new @flexoBag plate making technology To whom it may concern: We are a corrugated paper company with 6 flexo printer /slotter in our factory, before we make our own plate in plant, we are paying about USD 2000.- of photopolymer plates each month from the trade shops near around. Besides this, we have 10 people making hand engrave plate and a laser engraving machine making rubber plates for not so fine image jobs. Due to growing business, the owners have decided to make our own plate in our plant. Photopolymer plate making is a brand new item for us, so we have started to search for new technology of equipment and materials in order to improve our printing quality as well as for expanding our future business. Eventually, we have found @flexoBag System is a brand new technical for photopolymer plate making to meet our requirements of low investment, quick process and environment green for us. The total equipment cost with consumables for initial starting cost us USD .- for a 60 x 90 cm size machine which is quite practical for our use and quick process of the system has increased a lot of our productivity. By the end of December 2010, we are expecting to have our investment return, for we have found the total cost of the production including everything is less than 20% of the plates we rely on trade shop before. The owners know that using this new system is worth with no regret now.

Feedback from Indonesia PT PREMIER JAYA INDO

We are corrugated board company in Surabaya / Indonesia , due to labor wage increasing gradually and it is not easy to find skillful hand engraver to make rubber plate with many small letters on it, we must to find out a simple, easy economic and green way to make our own printing plate for printing the cartons in plant. Moreover, it is getting expensive for the plate we rely on trade house to make for us outside, so that we have to pay too much plate making fees every month, and it is becoming not a small sum as USD 20000.- annually. Therefore we start to search a good way to solve these problems for us and eventually we have found @flexoBag system from internet. The website is neat and clear enough to let us know everything about the new system with the DVD, the Q&A and the Feedbacks from their users by which we have found some of their users are in the very similar production situation with us. After having the comprehensive information, we have decided to place our order immediately in order to start up the plate making right after our New Year Holidays which is in the mid of September 2010. Two of @flexoBag engineers come from Taiwan at the beginning of October right after the machine had reached us and in 5 days, now we are able to make our own plate smoothly. Printers are happy because of no need to wait for plate delivery from trade shop any more or even have to go to collect the plate when we have to use it urgently.

I have to admit that we are not only happy with the @flexoBag system but also we have to thank them for their skillful and quick service offered to us to do training to our people for both plate making and for the machine maintenance. They are quite professional! Wenyao He

- NGHIEP -

CHIN CHIA PACKING & PRINTING FACTORY DONG-CHENG TOWN , DONG-GUAN CITY , GUANG-DONG , CHINA We are Chin Chia package printing company located in Dong Guan where is a major manufacturing city for all kind of goods export to most of the countries all over the world. Our job is making and printing film bags, paper bags and corrugated box supplying to the factories located in this area. At the beginning we use conventional flexo plate, but because of the green environmental requirement is getting higher and higher so that we have decided to find a more friendly method to make plates. We have made flexo plate by solvent washout for quite a long time, until it was a good chance for us to see this new announcement of water washout flexoBag system during DRUPA 2008 in Dusseldorf Germany, after the show we have made several visit to see the demonstration of how to make a bag, how to fill in the liquid resin, exposure, wash by water and request for making plates for our test printing on line to proof not only for the reproduction but also the long impression running of the plate made by the system for it is a brand new technology in the flexo printing industry. All of employees hate the strong solvent odor so much that we have to decide to use this water wash system as soon as possible. The solvent recovering department people, now they join us in printing room, for they have lost their job already. In addition to these, plate making room is no longer a dirty place like before any more. The happiest person should be our boss, not only for the production cost have been reduced 40-50% and processing time very short, most important is that the boss has returned all his investment back by now mostly because of using no solvent any more. In spring of 2009, we started to use @flexoBag plate making system, now we could not print without it for everybody love it, even our former plate making shop is using the same system following us. Pre press Dept. We are very happy and healthy with @flexoBag I am delighted to report that the @flexoBag system works well in our factory since July 2009. I made some excellent plates from liquid photopolymer by using the flexoBag system and use only water to wash it out, it is very incredible that the plate is the same quality with the solvent washout flexo plates. Now all the people in the prepress room are very happy with it because of no disgusting odor in the factory any more, every body looks very healthy now. Due to flexoBag can be prepared in advance before plate making, the bubbles are disappeared therefore it is very easy and quick (50% time consumption only) to use by just putting the film and bag in between two glasses do not have to pour in resin waiting for spreading and take off the bubbles on the machine, so the exposure process is now simple and easy for us in stead of the hard works of spreading the thin film and paving the base film (because the bubbles may happen again during this procedures). No spreader, no coater and no bubble happened, the machine is very simple so the cost of investments we have paid is only 30% of the conventional machine cost, plus the production cost is only 50% of the solvent wash flexo plates therefore we are expecting to have our return of investment quicker by June of 2010 definitely. All of our employees like this new flexoBag system very much Hen Cog 22-27 Tienmu West Road Taipei , Taiwan

Model : FB 4260 GT Exposure + Treatment Unit

@flexoBag System New weapon to substitute Engraving Plates A new solution to substitute engraving plates for corrugated board printing is now available from @flexoBag system which is a new weapon for the future business,the reasons are: • Good engraving machine is very expensive, however a low end machine and hand engraving can not satisfy the users anymore¡K..both trade shops and printers. • Engraving process is very slow and it is not easy to engrave it in fine detailed images, which can not meet the requirements of plate maker and printers. • Laser engraving companies odor smell as burning a rubber which is in high air pollution and bad to human health. • Environmental green is an important issue nowadays, odor smell, air pollution, and using of solvents are the trends to be avoid. While @flexoBag system is using a new patented technology to put liquid resin in a bag with free quantity and free seal to make a plate in any thickness and size according to your negative, the advantages are: • Water washout - Use water to washout the plate, no more solvent is required which all the plate makers are happy with it, the environment is clean and green now. • High productivity - Due to this new invention of @flexoBag, plate making is very quick now. To make 30 square meter of plates ( 4mm thickness) in 2 shifts each day is very simple and easy now. • Simple stock ¡V No more complicated stocks of various thickness and size to stock the plate by just preparing a pail of liquid photopolymer resin in 18 kgs or 200 kgs drum. • Low investment ¡V By using @flexoBag System the complete set of equipment investment is only 30 percent to a conventional liquid resin plate making machine. • Production cost is LOW ¡VThe production cost now is only 50% of a solid plate washout by solvent, for using water to washout the plate will save you solvent cost which is 20-30% of the plate cost • Employees are happy ¡V Your employees will be happy with you wise decision for they will work under a green environment and healthy than ever before.

No running-in period and skilled worker required For 35 years in package the company has been located in E-Land, the Eastern side of Taiwan ¡Van isolated area before the freeway was built five years ago (June 2006), due to inconvenient transportation from Taipei city areas (which is on the North-west side of the island). In the past it took around 4 hours to get there ¡Vnowadays it's only about 40 minutes when taking the tunnel (about 13 kilometers/8 miles). DJ Cartons operates three printer slotters for multi-colour carton printing to cater for the demand for packaging in the Eastern areas like Hua Lien and TaiTung counties. Now they have the ability to expand their territory to the city areas ; in Taipei DJ Cartons has opened a liaison office to take the orders after their own in-plant platemaking system from @flexoBag had been started. In the past DJ Carons had to rely on tradeshops in Taipei to make the plates. They spent around TWD 150,000 a month which was not competitive. The total annual expenses for platemaking amounted to TWD 2,000,000; some TWD 8.00 per square inch (6.5 cm 2 ). Now that DJ Cartons has started @flexoBag system, the total cost has come down to only TWD 1.80 square inch, which also includes the costs for making the negative. Using the LaserBlack Enhancer this is a very economic and convenient way for making a negative : all that is needed is a HP laser printer. The owners-two brothers-are happy with this new system as it has reduced plate costs by 75%. In addition : There is waiting time for plate delivery and the cost of transportation from West to East ; originals already having been sent online, which is quick. Two ladies in the factory were assigned to be trained as operators for platemaking for two days. They joined the production immediately, although they have had no previous experience with platemaking. They are very happy with their waterwash @flexoBag system as they do not have to stand the bad smell of washout solvent which is also toxic. The two lady operators have achieved the goal of meeting the slogan No running-in period or skilled worker required. New weapon as a substitute for engraving plates

@flexoBag System

Plate making tips @flexoBag liquid photopolymer plate • Storage: • Unexposed resin pail • Processed plate • Handling: • Preparing bags: • Make sure base film side with sticky back and mat side film is for keeping your plate surface smooth. • Seal together with heat sealer or tapes assure that no leak of the bag, especially double secure the 2 corners when the bag is very big. • Filling resin: area from the bottom valve into the bag by a high-pressured air compressor. • Then keep the bag in a standing rack one by one in order to be ready for exposure with negative film. • Exposure: • Due to resin already in the bag, therefore you may put the negative under the bag or upon the bag with no difference of plate making result. C. Total exposure time is 2-3 minute (4mm plate) ratio of back and film exposure time is depending on distance and kind of light source. D. You may cut off the 4 sides of the bag, now the plate (bag) is ready for washout. • Washout: • Drying • Post-exposure • Anti-tack exposure • Press ready

@flexo Bag Photopolymer

F-32 & F-40 for corrugated industry, F-50 for stamp making

@flexo Bag is a faster exposure, with fine reproduction details, water wash-out, easy and rapid operation. for a 4mm plate for corrugated board printing exposure time is only 5 min, wide latitude, fine details, no bubbles tolerance in + / - 0.03mm, good for all kinds of flexo printing. Now size available from A5 to A0. @flexo Bag Water wash-out is the best advantage of this system, no solvent means less drying time, quick ready as well as saving cost for plate making and environmental green. Water washout time is only 3 min. for a 4 mm plate. @flexo Bag Plus drying and anti-tack treatment whole process for a 4 mm plate is less than 20 min. Your existing plate making system is good enough for this system, only a new double side exposure unit is required. For more details please visit www.flexotech.com.tw.

@flexoBag Plate Making Trouble Shootings

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

![]()